Various Types of Plastics Used for Manufacturing by Plastic Bottle Companies

A typical plastic bottle company generally manufactures specialized plastic bottles, whether it is for food packaging or for medicines and related stuff. Because different types of bottles require different properties, many types of plastic are used for manufacturing bottles. Not all make different variants; PET bottle manufacturers use only PET plastic for PET bottles, but most companies use more than one form of plastic to increase their product diversity.

Here is a list of common types of plastics used for manufacturing by plastic bottle companies:

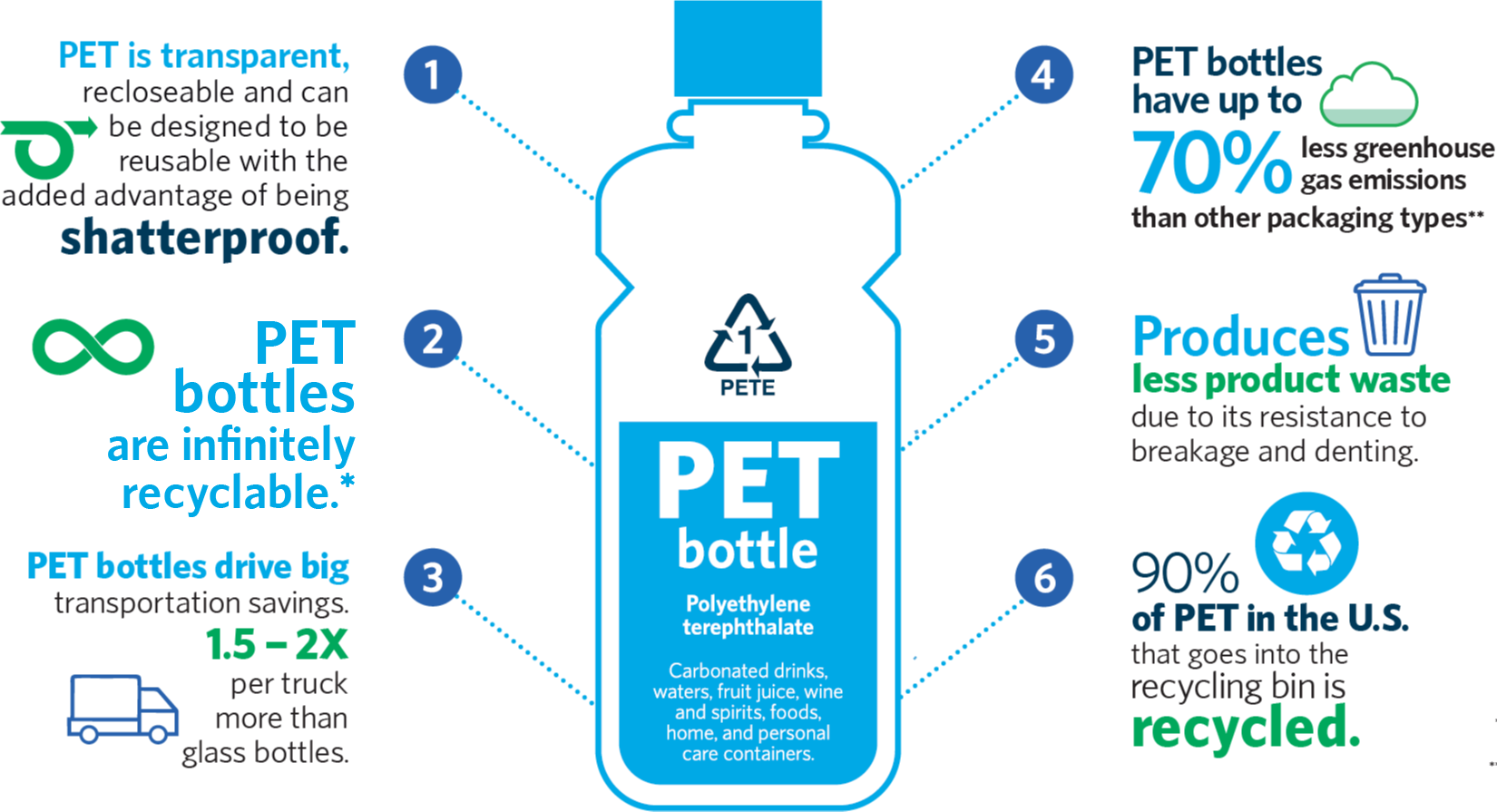

Polyethylene Terephthalate (PET)

It is the most common plastic used for making plastic bottles. PET bottles are generally used to store consumables such as food, beverages, and water. They are relatively inexpensive to produce and offer good protection against chemicals and external factors. They are also strong, although they need to be kept at room temperature or less for better protection.

High Density Polyethylene (HDPE)

It is a hard-plastic resin that offers unmatched strength for its price. It offers very high acidic resistance, hence mainly used to make containers for storing food, liquids, beverages and chemicals. Like PET bottles, it cannot be used for storage at high temperatures above 190 F, but are good for storage below freezing points.

Low Density Polyethylene (LDPE)

While they are somewhat similar to HDPE in terms of composition, LDPE bottles are not as strong or rigid, and offer less chemical resistance as compared to HDPE. However, because of this, they are very transparent, and are generally used for making small containers like squeezing plastics. Kids’ bottles, squeeze honey bottles: anything related to squeezing containers are made of low-density polyethylene.

Polyvinyl Chloride (PVC)

Many of us know PVC as an important component for making plastic pipes and PVC films, but what many of us don’t know is that PVC can also be made into plastic bottles and containers. It is great for making low-temperature storage containers and bottles, as PVC bottles have a low melting point of 160 F. They are not as popular, and not many companies make PVC bottles.

Polycarbonate (PC)

Polycarbonate is quite strong, but can be brittle at the same time. Hence, they are not that common in making plastic bottles and have limited applications. They are generally used to make large water and milk containers that usually sit in one place and not moved around, thus avoiding confrontation with its slightly brittle aspect.

Post-Consumer Resin (PCR)

Post-consumer resin typically means recycled plastic that is obtained from recycled HDPE plastic containers. They are quite economical and easily available, but their main drawback is that they cannot be bough in contact with consumables such as food, drinks and medicines. Hence they are used for making containers for storing non-consumable items.

Comments

Post a Comment